How a sportswear manufacturing cost sheet and pricing is done

publisherelsa

time2023/05/17

- This is the definitive guide to pricing and costing for starting a sportswear line.If you are starting a clothing business and want to find a clothing manufacturer for your business, you must know this

How a sportswear manufacturing cost sheet and pricing is done

With many different people involved in the creation of a sportswear piece and the various interests involved, it can be a complicated thing, but don't worry, we've got you covered. This is the definitive guide to pricing and costing for starting a sportswear line.

1. Factors in costing apparel:

The following factors determine the price of an athletic garment:

Fabric trim costs: cutting, fabrication and trimming

Value-added services including printing, embroidery, washing, ironing, laser and appliqué

Evaluation of the garment

Quality

Cost of logistics and transportation

Revenue generation for the manufacturing company

These factors have a significant impact on the cost parameters of an athletic garment. These variables are very dynamic and constantly changing, so they are critical when calculating the cost of producing fabric for apparel.

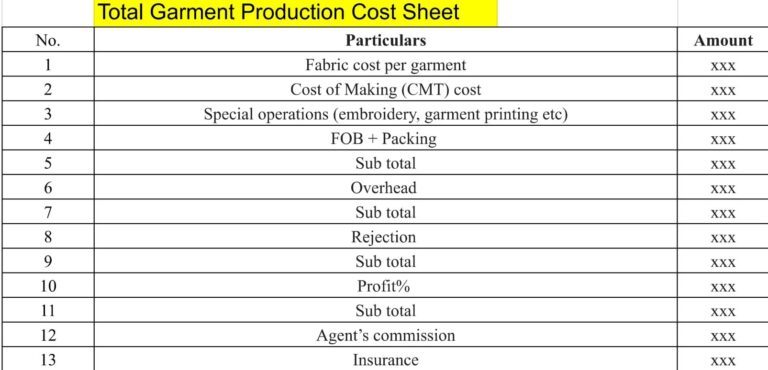

2.What is a cost sheet for the sportswear industry?

The total cost of a product or process can be calculated using a costing sheet, which is a report or format where all costs are systematically entered. A worksheet is an alias for it. Apparel costing sheets are very important in apparel manufacturing.

3.How do you create a cost sheet in the sportswear industry?

The perfect cost sheet should be simple and straightforward, yet comprehensive enough to provide all the necessary details about the garment you are making. You can create neat, well-organized cost sheets that track every expense, both as a record and as a reference tool.

Many companies still use Excel for costing purposes, such as embroidery pricing spreadsheets, fabric gram weight prices, cross-border logistics shipping prices, etc.

4. the main elements of a sportswear costing sheet

a. Initial costs: Direct materials, direct labor and direct costs make up the main costs. Basic cost, fixed cost and initial cost are the other names for it.

--- Primary cost is equal to the sum of direct costs (DM, DB and direct expenses) (DE)

b. Manufacturing Cost: The original cost and engineering or factory overhead constitute the factory cost or job cost. It is sometimes referred to as the cost of production for apparel manufacturing cost estimation.

--- Manufacturing cost is equal to original cost plus factory overhead.

c. Office Cost: Manufacturing or work overhead, and office and administrative overhead, make up office cost.

--- Office cost is equal to factory cost or job cost plus administrative and office overhead.

d. Total Cost: Total cost is calculated by adding the selling and distribution expenses and the definition of the production cost of the goods sold (i.e., apparel). It is also referred to as "cost of goods sold".

---Total cost of sales is equal to the selling and distribution overhead plus office costs.

As a new sportswear brand company, it can be very intimidating when you first see the cost of manufacturing apparel chart. You just want to know, "Is this a fair price for my product?" But please note that high margin items need to be made with good materials, well made, and quality is more important than marketing.

Understanding apparel cost sheets will give you further insight into brand pricing if you are running an apparel business and want to find an apparel manufacturer for your business. Therefore, it is important that you keep these costing sheets and pricing guidelines in mind.

To inquire more about price pricing please contact us!

Contact information:

INS:mens_activewear_hc

FACEBOOK:Hcmensactivewear Hucaiactivewear

E-mail: admin..........com

Whatsapp:+8613602338395